A 19MM metal switch with LED and a power logo combines compact functionality with intuitive visual communication

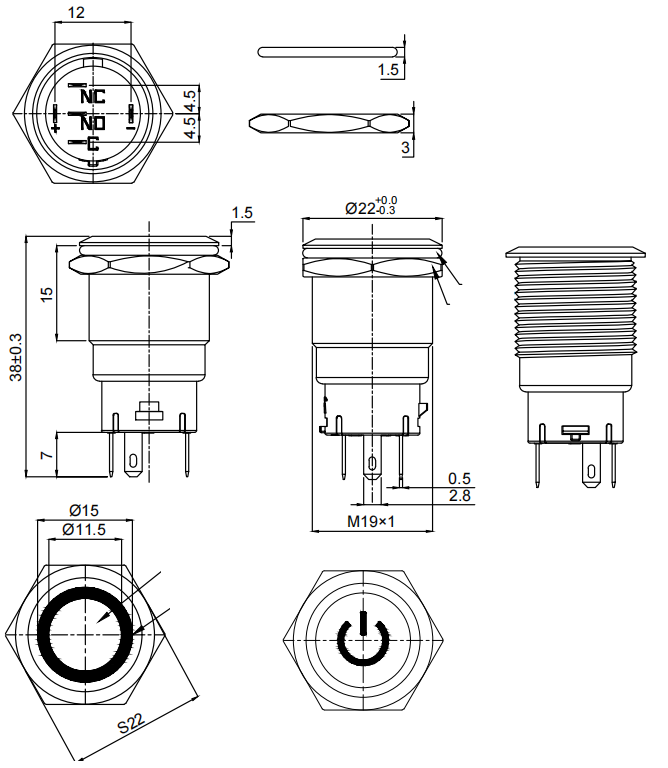

A 19MM metal switch with LED and a power logo combines compact functionality with intuitive visual communication, making it a staple in industrial control panels, outdoor equipment, and machinery where quick status recognition is critical. This design builds on the core features of 19MM LED metal switches while adding a power logo—typically a universal "power" symbol (a circle with a vertical line)—to enhance user clarity, all while preserving the waterproof and durable traits essential for reliable operation.

The integration of the power logo requires careful consideration of both aesthetics and functionality, especially in the compact 19MM metal switch form factor. Most commonly, the logo is etched, laser-engraved, or printed onto the switch’s metal actuator—the visible button that users press. For illuminated logos, the LED (often a small SMD or through-hole diode) is positioned to backlight the logo, ensuring it glows uniformly when the switch is active. This demands precise alignment: the LED must sit directly beneath the logo’s cutout or translucent section to avoid uneven lighting, a challenge in 19MM switches where space is limited. Manufacturers often use light-diffusing materials or micro-prism structures within the actuator to spread the LED’s light evenly across the power logo, preventing hotspots and ensuring visibility even in bright environments.

Waterproofing remains a key concern, as the addition of a logo (especially an engraved or cutout design) introduces potential weak points for moisture ingress. To maintain IP ratings (such as IP67), the logo’s edges are sealed using techniques like overmolding with clear silicone or UV-cured adhesives, which fill micro-gaps around the engraving without obscuring the logo. This complements the O-ring sealing system critical to 19MM metal push button switches: the O-ring, typically silicone or fluorocarbon rubber, sits between the actuator and housing, forming a primary barrier against water, while the logo’s seal acts as a secondary defense, protecting the LED and internal electronics from condensation or direct splashes.

Durability is another focus, as the power logo must withstand frequent actuation and harsh conditions. Laser engraving is preferred for metal actuators (like stainless steel or brass) because it creates a shallow, precise groove that resists wear—unlike printed logos, which can fade or peel over time. For added resilience, some designs coat the engraved logo with a wear-resistant clear epoxy, preserving visibility even after thousands of presses. The LED itself is often potted in epoxy within the switch housing, shielding it from vibration and moisture, ensuring the backlit logo remains functional alongside the switch’s core operation.

Contact: Ms Bella

Phone: +86-15999819066

Tel: +86-0769-89615395

Email: Bella@fvwin.com

Add: No 25, Xinfeng East Road, Shijie Town, Dongguan, GD, CN, 523000

We chat