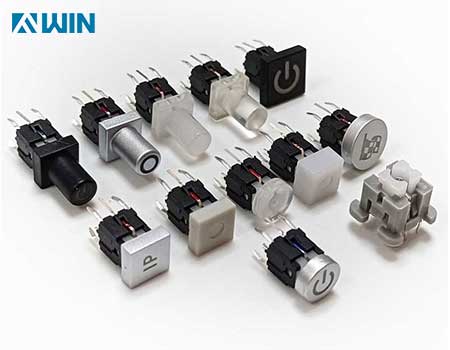

The illuminated led tact switch is mainly consist of top button, metal dome, cover and plastic base and the lead terminal. because of the tiny resistance, precise operation and various specifications advantages, the momentary LED tactile switch is widely used for home appliances and control panels.Now.let us introduct the illuminated led tactile switch common problems.

LED tactile switches are popular components in many electronic systems due to their tactile feedback and visual indication. However, like all electronic components, they can experience issues that affect performance, reliability, or usability. Below are some of the common problems with LED tactile switches:

Problem: The LED inside the switch may fail to light up, or it may become dim over time.

Causes:

Incorrect Voltage: If the switch is exposed to a voltage higher than its rated voltage, the LED may burn out. Conversely, too low of a voltage can cause insufficient brightness.

Overcurrent: Too much current can overload the LED, leading to failure. This is especially common if the current-limiting resistor is not properly sized.

Poor Quality LED: Low-quality or poorly manufactured LEDs may fail prematurely.

Circuit Design Issues: Inadequate circuit design, such as improper resistor values or poor PCB layout, can result in insufficient current limiting or voltage instability for the LED.

Problem: The tactile feedback from the button (the "click") might feel inconsistent or absent entirely, which impacts the user experience.

Causes:

Worn-out Mechanism: Over time, the snap-action mechanism inside the switch can wear out due to frequent use, leading to diminished or no tactile feedback.

Dirt or Debris: Dust or dirt can get into the switch mechanism, causing friction and preventing smooth operation. This can lead to a loss of tactile feedback or a sticky feeling when pressing the button.

Manufacturing Defects: Sometimes, switches may be poorly manufactured, with an internal spring or mechanism that doesn’t provide adequate or consistent feedback.

Inadequate Lubrication: Insufficient lubrication of internal moving parts can lead to resistance and hinder the tactile feedback, especially in low-quality switches.

Problem: The switch might produce multiple signals or "bounces" when pressed, causing erratic behavior or false triggering in the circuit.

Causes:

Mechanical Bounce: Mechanical switches, including tactile ones, can experience bouncing when the contacts close, leading to multiple unintended transitions. This is particularly problematic in digital circuits where precise control is needed.

Insufficient Debouncing: Lack of proper debouncing in the circuit or software can lead to multiple signals being sent when the button is pressed or released. A software debounce routine or a hardware debounce capacitor is typically used to mitigate this issue.

Low-Quality Contacts: If the contacts are of poor quality or poorly aligned, bouncing can be exacerbated.

Problem: Loose or poorly soldered pins can result in unreliable connections, leading to intermittent or complete failure of the switch.

Causes:

Cold Solder Joints: Improper soldering techniques can result in cold solder joints, which may not conduct electricity reliably. These joints are often weak and prone to breakage, leading to signal loss or inconsistent operation.

Overheating: Excessive heat during soldering can damage the switch or its internal components, such as the LED or contacts.

Poor Pin Alignment: Misalignment of switch leads when mounted on the PCB can result in broken connections or improper function.

Problem: The switch might become stuck in one position or fail to return to its neutral state after being pressed.

Causes:

Dirt or Contaminants: Dirt, dust, or contaminants can build up in the switch mechanism, preventing the button from returning to its original position. This can cause the button to stay pressed or not activate properly.

Manufacturing Defects: A defect in the internal mechanism (e.g., misaligned parts or incorrect spring tension) can cause the switch to become jammed or stuck.

Overpressure: If excessive force is applied during pressing, the switch mechanism can become damaged, leading to a stuck button or loss of tactile feedback.

Problem: The LED inside the switch may emit uneven lighting, flicker, or fail to display the intended color.

Causes:

LED Quality Issues: Low-quality LEDs or poor soldering connections can cause inconsistent illumination, such as dim spots, flickering, or color inaccuracies.

Incorrect Resistor Values: If the current-limiting resistor is not correctly chosen, the LED may not receive the proper current, leading to issues like dimming or failure to light.

Voltage Fluctuations: Voltage variations or power supply instability can lead to irregular LED brightness or flickering.

PCB Design Issues: Poor PCB routing or design can result in uneven power distribution to the LED, leading to inconsistencies in illumination.

Problem: The LED tactile switch may cause electrical noise or interference, particularly in sensitive circuits, leading to malfunctions.

Causes:

Inductive or Capacitive Coupling: Tactile switches with integrated LEDs could introduce noise into nearby signal lines if the switch is located too close to sensitive circuits or high-speed signal lines.

Incorrect Circuit Grounding: Improper grounding in the PCB design can cause issues with noise and signal interference, which might affect the performance of the switch or the attached electronics.

Switching Power Supply Noise: If the LED is powered by a switching power supply, noise from the power supply could interfere with the button's operation, causing unexpected behavior.

Problem: The switch may not make proper contact, leading to unreliable operation or failure to trigger actions.

Causes:

Weak Springs: If the internal spring mechanism of the switch is too weak, the contacts may not engage properly, leading to unreliable activation.

Dirt or Corrosion: Contaminants or corrosion on the contacts can prevent proper electrical contact, leading to issues like inconsistent triggering or total failure to register a press.

Overuse or Wear: Over time, the contacts can become worn out or lose their original tension, which can lead to reduced pressure and poor contact.

Problem: External factors, such as humidity, temperature, or exposure to liquids, can cause the switch to malfunction.

Causes:

Moisture or Water Exposure: LED tactile switches that are not rated for water or dust resistance may fail when exposed to moisture, leading to corrosion or electrical shorts.

Extreme Temperatures: High or low temperatures can cause materials inside the switch to expand or contract, affecting its functionality or reliability.

Static Electricity: Electrostatic discharge (ESD) from handling or environmental factors can damage the internal components of the switch, especially the LED or the tactile mechanism.

Problem: If the actuator is not properly aligned or seated in its housing, it may not function correctly.

Causes:

Manufacturing Tolerances: Tolerances in manufacturing can cause slight misalignment of the button actuator, preventing it from pressing the internal switch mechanism properly.

User Mishandling: If excessive force is applied to the button, or if it is subject to repeated impact or misuse, it can cause the actuator to become misaligned.

LED tactile switches are durable and reliable components, but like any electronic device, they can experience issues that affect performance. Common problems such as LED failure, inconsistent tactile feedback, contact bounce, soldering issues, and environmental factors can all lead to malfunction or reduced performance. Proper design, handling, and maintenance can help mitigate many of these issues, but users must ensure they choose high-quality components and follow best practices in circuit design, assembly, and operation to ensure the longevity and reliability of these switches.

Contact: Ms Bella

Phone: +86-15999819066

Tel: +86-0769-89615395

Email: Bella@fvwin.com

Add: No 25, Xinfeng East Road, Shijie Town, Dongguan, GD, CN, 523000

We chat